Understanding ceramic materials is based on a broad foundation of fundamental knowledge. This begins with chemical bonding and the structures of solids. The path from raw material to the final product is determined, on the one hand, by possible equilibria and, on the other, by reaction rates, i.e., kinetics.

Important statements about this are possible through thermodynamics. This also defines the structure of this lecture. Only after addressing these physical-chemical principles and some of their properties can the processes involved in the production of ceramic bodies and their further processing be examined in more detail, in order to gain a deeper understanding of the various types of ceramic materials.

The following content is covered in detail:

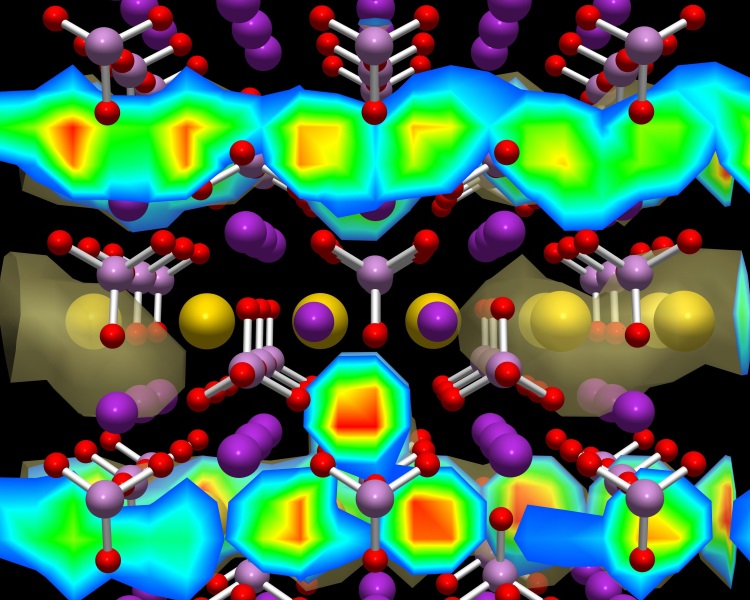

- Introduction, structures of ceramic materials, bonding types

- Crystal forms, lattice energy, systematics of silicate ceramics and technical ceramics

- Surfaces, surface tension, determination of specific surface area and grain size

- Thermodynamics and kinetics of ceramic materials, crystallization, microstructure of ceramic materials

- Diffusion, reactions, sintering kinetics, liquid-phase sintering, pressure sintering

- Ceramic systems: single-, two-, and three-component systems (components, phase diagrams)

- Preparation, raw materials, colloid chemistry, fundamentals of rheology, organic additives

- Shaping, drying, firing, phase formation during firing, engobes and glazes

- Production and properties: porous and dense clay ceramics, stoneware and porcelain (transparency, mechanical and thermal properties)

- Refractory materials, mechanical, thermal and chemical properties

- Structural ceramics, production and properties, overview

- Oxide and non-oxide ceramics, properties and Applications

- Microstructure-Property Correlations of Ceramic Materials, Ceramography

[Self-registration for the lecture is done using the ID #KERGL2025_26#]

- Dozent: Priv.-Doz. Dr.-Ing. habil.: Guido Falk